Access laboratory documents

Nano- and Micromechanical Lab

The nano- and micromechanical lab within the SMART-H project is dedicated to understanding the hydrogen-material reaction at a nano- to micro-scale. In-situ and ex-situ hydrogen-charging approaches are specially designed for small-scale mechanical testing. Instrumented nanoindentation and small-scale tensile tests are the most frequently used testing techniques. The combination of the small-scale mechanical testing and ex-situ/ in-situ hydrogen-charging can reveal a wide range of material’s intrinsic physical behavior when in reaction with hydrogen.

Equipment

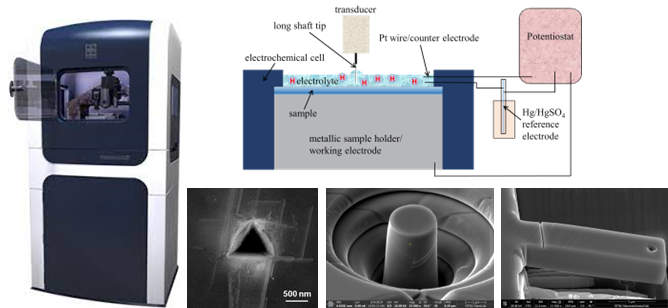

TI950 nanoindenter (Bruker): feasible for ex-situ & in-situ electrochemical charging

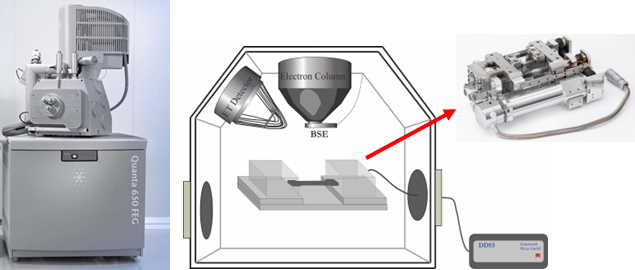

PI85 nanoindenter 1 (Bruker): feasible for ex-situ charging & in-situ hydrogen-plasma/ ESEM (water vapor) charging

5 kN tensile/ compression module 1 (Kammrath & Weiss): feasible for ex-situ charging & in-situ hydrogen-plasma charging

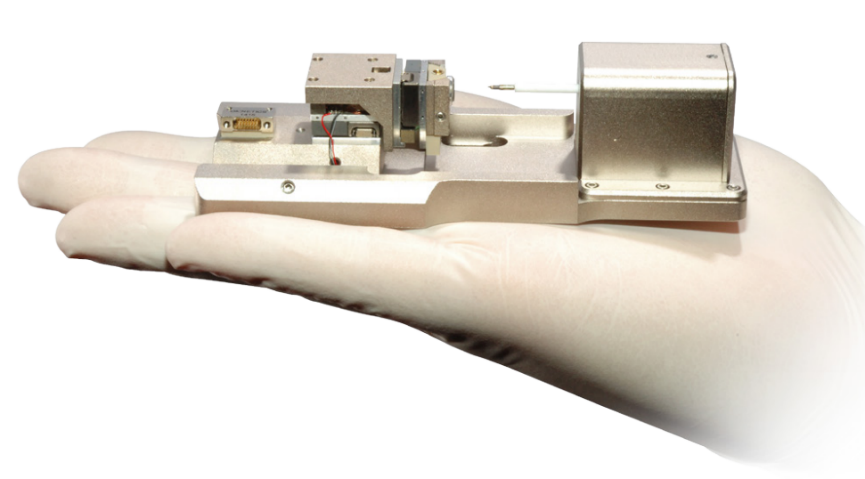

FT-NMT04 nanoindenter 1 (FemtoTools) (in progress): feasible for ex-situ charging & in-situ hydrogen-plasma/ hydrogen gas 2 charging

Small-scale autoclave 3 for in-situ high pressure gaseous hydrogen – material interaction

1 can be integrated into SEM

2 up to 1.3 bar hydrogen pressure

3 in progress

Laboratory Contact

Dong Wang

Laboratory manager

Location

NTNU

Richard Birkelands Vei 2B

Trondheim

Norway